Plug & Spray - GM High Tech

Though admittedly the sick House of Kolor paintjob makes me less inclined to daily drive our long-running LT1 Formula project, the mission was a simple and reliable 11-second daily driver on a moderate budget. Some may say that this was not the most ambitious of goals. However, those experienced in the ways of the Gen II SBC will know this was a harder task than it seems. And besides, you have to crawl before you can walk. Nevertheless, I am pleased to say that the day is near at hand thanks to the Nitrous Outlet and Tune Time Performance in Toms River, New Jersey. Thankfully we had already rebuilt our bottom-end, a necessary evil whenever swapping heads and/or a cam into an LT1, so we felt confident spraying the aging beast without spinning a bearing. And having known Nitro Dave for quite a while, we were also confident in his product-especially given the long list of fast LT1s currently running this system.

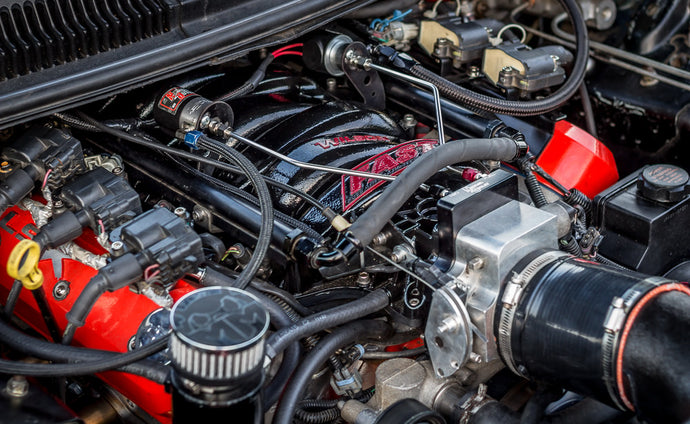

The new Nitrous Outlet 93-97 LT1 Specific System is one of the first and only kits literally designed specifically for an application, instead of simply adapting a universal kit. This means every little detail down to the mounting hardware is specific, so you don't have some sloppy solenoid bracket hanging off the intake manifold. No sir, this wet-plate system has a single (and stylish I might add) mounting bracket for the solenoids with pre-bent stainless steel hard lines that connect to the plate, which easily and neatly bolts to the top of the intake manifold. The plate is designed to be the best fitting, best atomizing, and highest flowing unit on the market. The same care was taken in selecting high-flowing, bottom exit solenoids designed to work with current fuel cocktails (including E85). The kit we chose (PN 00-10117-58-10) accommodated our dual-blade 58mm Edelbrock throttle body, and came with a 10-pound bottle. There are other variations of this kit for a 52mm or monoblade, 15-pound bottle, or a bottle delete. All kits come with jetting to support a 50 to 200-horsepower shot, however the components will support up to 400 hp-all of which are made in the USA, by the way. Texans don't mess around!

Leave a comment